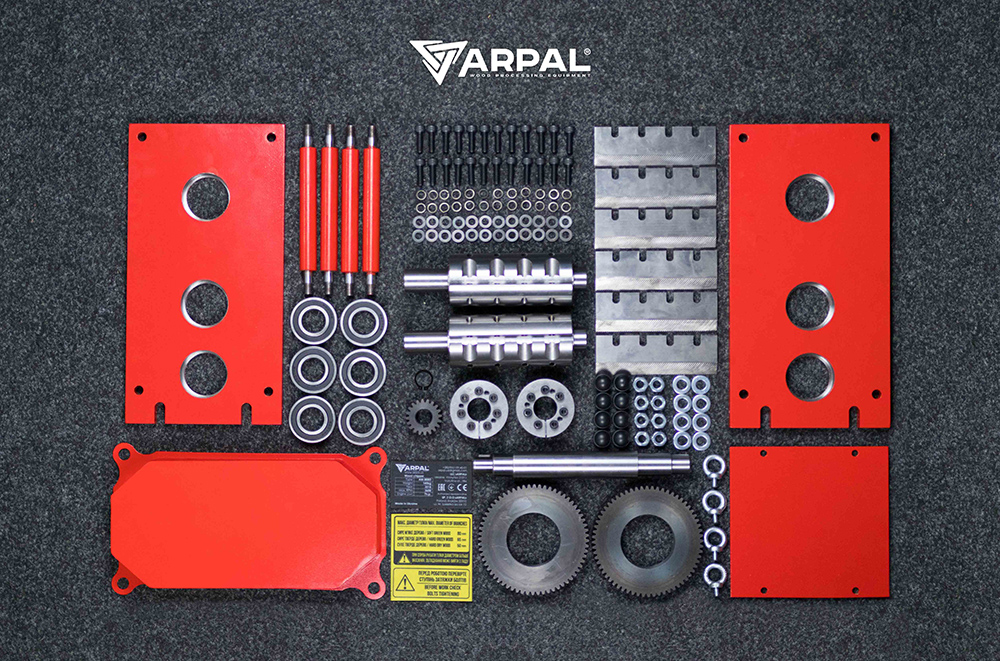

1️⃣ Special design of working shafts. The shaft is designed and manufactured in such a way as to distribute the load on the body of the shaft itself and reduce the load on the fasteners (bolts). Also, an advantage of this design is the ability to accurately position the blades relative to each other. Due to this, the distance between the knives is less than one millimeter and allows you to chop thin branches, even after a long life of the chopper. Such characteristics cannot be achieved on square shafts.

2️⃣ Knives. Knives are the main working element of the grinder. They first take on shock loads during operation and, accordingly, are a consumable element. At the same time, knives present special technical requirements that can be achieved using only certain steel grades and with its correct processing. In the ARPAL branch shredders, the knives are made of alloyed, chrome steel grade 40X, which shows excellent mechanical characteristics of strength and toughness. And heat treatment for hardening the cutting edge of the knife increases the resource of the part, while leaving the necessary properties for absorption and transmission of mechanical impulses to the design of the grinder. Double sharpening angle allows you to extend the life of the knife, without affecting its working qualities.

3️⃣ Coupling. The clutch between the shaft and the gear is provided through a taper self-locking coupling. This design makes it possible to position the knives relative to each other, which in turn allows you to chop thin and damp branches, while not jamming and chewing them. Such a design advantage requires high precision metalworking and a clean surface finish, which is achieved only using high-quality and well-tuned equipment and is often not available to unskilled manufacturers and amateurs. In addition, the clutch serves as an extreme protective mechanism and under critical loads will not damage the working shafts of the chopper. When landing on the splines, the exact positioning of the shafts relative to each other is almost impossible!

4️⃣ Gears. The design of the chopper branches designed and designed for one specific task, for maximum efficiency of its implementation. Gears designed specifically for work in this mechanism are manufactured at our enterprise. This allows you to control the quality of work at all stages of production, starting from the procurement of raw materials. This design makes it impossible to use gears from third-party mechanisms and gives 100% confidence in the quality of the used components.

5️⃣ Plates. In each plate, with the help of a high-precision Italian boring head, three bearing seats are made. The plates of the cutting module are made of steel 20 mm thick (depending on the model), each plate is coated with powder paint, which reliably protects the plates from mechanical damage and corrosion.

6️⃣ Protective elements. On the frame and the cutting module, we install plastic plugs to prevent corrosion of the mechanism from the inside. All work items are protected by housings to protect the operator from contact with parts that rotate.

7️⃣ Bolts. The knives are attached to the shafts using bolts of strength class 12.9 German production.

8️⃣ Certification. ARPAL branch shredders have been tested in laboratories and received CE certificates, confirming compliance with European Union standards. The equipment is protected by patents for industrial design and structural solutions.

By the link you can buy and evaluate the quality of the wood chippers and Wood shredders of our production.