AM-60BD

| Length | 1153 mm |

| Width | 532 mm |

| Height | 976 mm |

| Weight | 97 kg |

| Inlet slot size | 93х99 mm |

| Тип приводу | Бензинові |

| Max. productivity | 2 m3/h |

| Soft wood max. diameter | 60 mm |

| Hard wood max. diameter | 50 mm |

| Length of ready pieces | 60-100 mm |

| Quantity of knives | 4 pcs |

| Engine power | 7 h.p. |

| Max. turns on engine shaft | 3600 rpm |

| Fuel type | Regular |

| Max. fuel expenditure | 230 g/h.p.*hour |

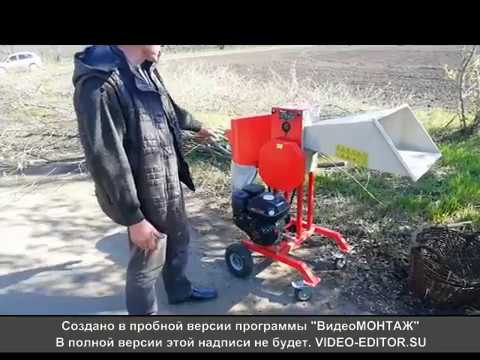

The AM-60BD wood chipper is designed for processing and disposal of branches, rails, slabs, lamellas, and other wood waste by chopping them into pieces. The chipper converts raw material into pieces 6...10 cm in length, a size that cannot be adjusted and depends on the diameter (thickness) of the material. The AM-60BD wood chipper can cut branches up to 6 cm in diameter, depending on the moisture content and type of wood. The chopped branches are ideal fuel for pyrolysis and solid fuel boilers, fireplaces, stoves, and other heating devices, as well as for charcoal production.

The AM-60BD wood chipper is perfect for home use. With this chipper, you can process not only branches but also grapevines, rose stems, corn stalks, etc. The productivity of the AM-60BD wood chipper is up to 2 cubic meters of finished product per hour of operation. The output depends directly on the quality of the prepared raw material and the number of personnel involved in the work.

Engine and Overload Protection

The AM-60BD wood chipper is equipped with a gasoline engine with a power output of 7 hp, manufactured by Loncin. Its fuel consumption is only 500 g/h. This engine is one of the most reliable in Ukraine, with service centers available in every region. The engine is protected from overload by a special friction clutch, which ensures smooth startup, prevents sudden stops, and facilitates the release of jammed branches. The engine comes with a separate 12-month manufacturer’s warranty.

Cutting Mechanism

The cutting mechanism consists of two plates, a drive shaft, and two working shafts with knives. The mechanism is equipped with its own gearbox that increases the torque by 2.2 times and consists of three gears. Bearings are fully seated in the body of the plate, ensuring proper operation, easy maintenance, and protection from damage. The gears are connected to the working shafts using conical quick-release couplings. This type of connection is a key difference from other manufacturers that use rigid connections like splines or keys, which over time lead to irreversible damage or costly repairs.

Conical couplings serve several functions:

- They allow for precise alignment of the knives in a single plane.

- They help adjust the cutting mechanism and avoid loosening during operation.

- They prevent damage to the cutting module when the load is exceeded.

The working shafts are ground, ensuring a tight fit of the conical couplings. The couplings transmit the required working load and slip only under extreme loads to prevent damage to the equipment. This design of the cutting mechanism allows the chipper to handle even the thinnest branches, which improves the quality of the chipped material, as all pieces will be evenly separated. In other chippers, if the knives are not precisely aligned with a minimal gap, the branches may be incompletely chopped, forming “sausages,” which complicates further use of the material.

Each component of the cutting module is manufactured separately on CNC machines. This ensures high accuracy, quality, and alignment of the cutting elements. The precise fits and perfectly flat surfaces allow the module to be assembled precisely. The mechanism operates smoothly, like a clock. In a welded structure, there is a high risk of misalignments and deformations during welding, leading to the loss of proper geometry and alignment of the cutting module. Initially, these issues may not affect performance, but after prolonged use, they will result in serious breakdowns. What’s more, such issues are impossible to fix in welded designs, unlike in modular constructions, which can be completely disassembled with a single wrench and each part replaced.

Knives

The working element of the wood chipper is the knives. The AM-60BD wood chipper is equipped with 4 knives made of 40X steel, featuring a double sharpening angle and undergoing mandatory heat treatment in a modern induction heating system. The knives are inserted into a milled groove on the working shaft, a technology that significantly reduces the load on the bolts securing the knives.

Frame and Wheels

All the components of the wood chipper are mounted on the frame, which is made of thick-walled tubing and has a rigid structure. The chipper is equipped with wheels for convenient movement around the area.

Output Hopper. Firewood Packaging

The AM-60BD wood chipper is equipped with a straight output hopper that allows branches to be chopped directly onto the ground or into a low container. The output hopper design is very rigid and reliable, able to withstand impacts from branches. The hopper directs the branches in a single clear direction, and all other sides are enclosed, which, unlike designs from other manufacturers, prevents branches from flying towards the operator or deforming the hopper.

Input Hopper. Operator Safety

Raw material is fed through the input hopper, which has a rigid construction (tapping with the hand reveals its sturdiness), reinforced with ribs around the circumference and further strengthened with a channel below to resist branch impacts. A safety handle is mounted on the hopper for the rapid shutdown of the equipment. This handle also serves another function: it allows for easy movement of the chipper around the area.

The length of the hopper meets the safety standards of the European Union for forestry machines. The dimensions of the input opening are 93x99 mm.

The AM-60BD wood chipper is entirely manufactured in-house. We control the quality of all stages of production, with all mounting surfaces being mandatorily ground. The quality of the welded seams is also inspected. Before painting, all structures are cleaned, and the wood chipper is coated with powder paint, significantly extending the life of the chipper’s parts.

Unique Feature

A standout feature of all ARPAL wood chippers is that no additional tools are required for operation. Preparing the chipper for work and getting it started can be done without the use of additional wrenches.

Warranty and Service

Customer service and focus are significant advantages of ARPAL. We always strive to assist our clients as quickly as possible with any issues that may arise during operation. A QR code is located on the input hopper, providing instant contact with the factory’s specialists, which is extremely convenient.

We are confident in our product, so we offer a 3-year warranty on the AM-60BD wood chipper. Additionally, as the manufacturer, we provide both warranty and post-warranty service for the AM-60BD wood chipper.

By purchasing a wood chipper from us, you are gaining a reliable assistant on your path to energy independence!