Wood chipper AM-200TR-K PRO

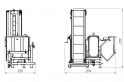

| Length | 2014 mm |

| Width | 1201 mm |

| Height | 2250 mm |

| Weight | 925 kg |

| Inlet slot size | 285х255 mm |

| Axle mounting diameter to tractor | 28 mm |

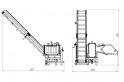

| Height of the conveyor | 4 m |

| Тип приводу | Тракторний |

| Max. productivity | 14 m3/h |

| Quantity of knives | 6 pcs |

| Max. turns on cutting knives | 104 rpm |

| Rec. engine power | 130 h.p |

| Engine min. power | 80 h.p. |

| Max. turns on PTO | 540 rpm |

Wood chipper AM-200TR-K is designed for processing and recycling by cutting branches, rods, duplexes, lamellas and other wood waste. The shredder of the branches turns the raw material into pieces, size is not regulated but depends on the diameter (thickness) of the raw material. The wood chipper AM-200TR-K is capable to cut branches up to 20 cm in diameter depending on humidity and wood species. Chopped branches are ideal fuel for pyrolysis and solid fuel boilers, fireplaces, stoves and other heating appliances, as well as for the production of charcoal.

The productivity of the AM-200TR-K is up to 14 cubic meters of finished products per hour. Productivity directly depends on the quality of raw material preparation and the number of personnel involved in the work. The wood chipper AM-200TR-K is driven from the tractor PTO shaft and mounted on a standard three-point linkage. The minimum required power of the tractor for working with the chopper branches is 80 hp. To connect the tractor to the chopper, we recommend using a cardan shaft of class Z6 with a friction and overrunning clutch that protects the chaff from the branches and the tractor from overloading.

The working element of the wood chipper is knives. The wood chipper AM-200TR-K has 6 knives, the knives are made of AISI 5140 steel, have a double grinding angle and necessarily pass the heat treatment process on a modern HIGH FREQUENCY INDUCTION HEATING MACHINE installation. Cutting knives are inserted into the milled groove of the working shaft, this technology significantly reduces the load on the fixing bolts of the knives. The AM-200TR-K is equipped with a conveyor that allows you to feed the chopped material directly to the car trailer or to a special container (container, big bag). The conveyor allows to significantly increase labor productivity and reduce the number of personnel during work.

By raising the wood chipper on the coupler hydraulics, you can increase the height of the load. In conveyors we use only high-quality PVC tapes produced in Poland or Holland.

The wood chipper AM-200TR-K is completely produced at our enterprise. We control the quality of all stages of our production, all landing surfaces are obligatory grinding. Quality control of welded joints is carried out. Before painting, all constructions are stripped. The shredder is covered with powder paint, which significantly extends the life of the constructions.

We are confident in our products; therefore, we provide a 36-month guarantee for the AM-200TR-K. In addition, we, as a manufacturer, produce both guarantee and post-warranty maintenance of the wood chipper AM-200TR-K.

By purchasing a wood chipper from us you get a reliable assistant on the way to your energy independence!