The process of production of wood chippers takes place on a modern CNC machines, which allows us to get high-quality products. Our equipment is developed by advanced engineers with a high level of qualification with a new modern look at technology.

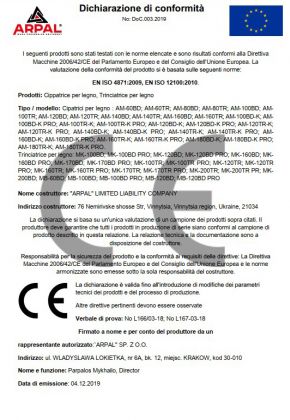

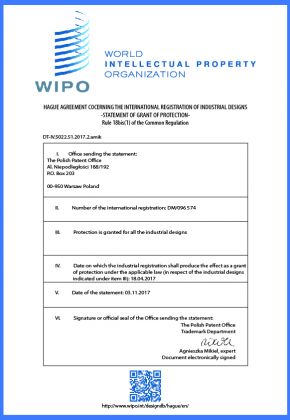

All work on the production of wood chippers is carried out on high-qualitative equipment by the best specialists in their field. The assembly of wood chippers takes place under strict control and attention to all details. We are confident in our production therefore we give a guarantee for our wood chippers!

All working elements of the machines are thermo-treated by high-frequency currents and this significantly extends the service life of the parts

The knives of our chippers have a double angle sharpening, which greatly extends the service life of the cutting element

The input hoppers are equipped with a safety handle that allows the operator to turn the machine off in case of emergency or when needed

All the Arpal machines are coated with high-qualitative powder paint, which secures the body of the chipper from corrosion and mechanical impact of branches.

The gap between the blades is less than 0,2 mm

This clutch allows to start the engine smoothly and prevents abrupt engine stops during critical loads (because of thick branches or knots hitting inside)

A double-bag output hopper is installed on the model of the AM-120 machine, which allows you to pack wood logs into two bags at once continuously. This option greatly increases the performance of the chipper

For the most accurate and barrier-free positioning of knives, long operation and additional protection

The design of the working shafts increases the operation torque, which is transmitted from the drive to the chipper knives. Unlike the square shaft, here the load is perceived not by the knife, but by the shaft body itself, because the knife is seated in the milled groove. As a result, the service of the the cutting element lasts much longer

Provide the most accurate part processing and consistently high-qualitative equipment

- Forestry

- Wood waste recycling

- Garden farms

- Farms

- Recreation facilities

- Parklands

- Plant nurseries

- Landscape design

- Arboristics

- Road service

- Wood processing

- Utilities and housing services

- Heating

This site uses cookies for a more comfortable user experience. By continuing to browse the site you agree to the use of cookies. If you need more information or do not want to accept the use of cookies, please visit "About cookies"